Environmental Testing

Food Safety Modernization Act (FSMA)

Environmental monitoring has always been a critical component of a comprehensive food safety and quality program. But with the advent of the Food Safety Modernization Act, environmental monitoring is shortly going to be a required component for many types of facility, particularly if there are particular pathogen risks requiring preventive controls.

While FSMA refers to the value of testing and circumstances for which testing is indicated, it does not clearly outline what specific types of facilities should be doing for environmental testing. MarketFresh can help you in deciding what would be best for your unique facility.

Benefits of Environmental Testing

There are numerous benefits which make environmental testing critical to ensuring a safe production facility.

- Ensure cleaning and sanitation programs are working and effective against microorganisms

- Assess the frequency needed for cleaning and sanitation programs

- Measuring the effectiveness of cleaning of equipment and potential niches which could harbor microorganisms

- Identify “hotspots” and high risk areas that may need additional care during cleaning

- Reduce risk potential for pathogen contamination from the production environment

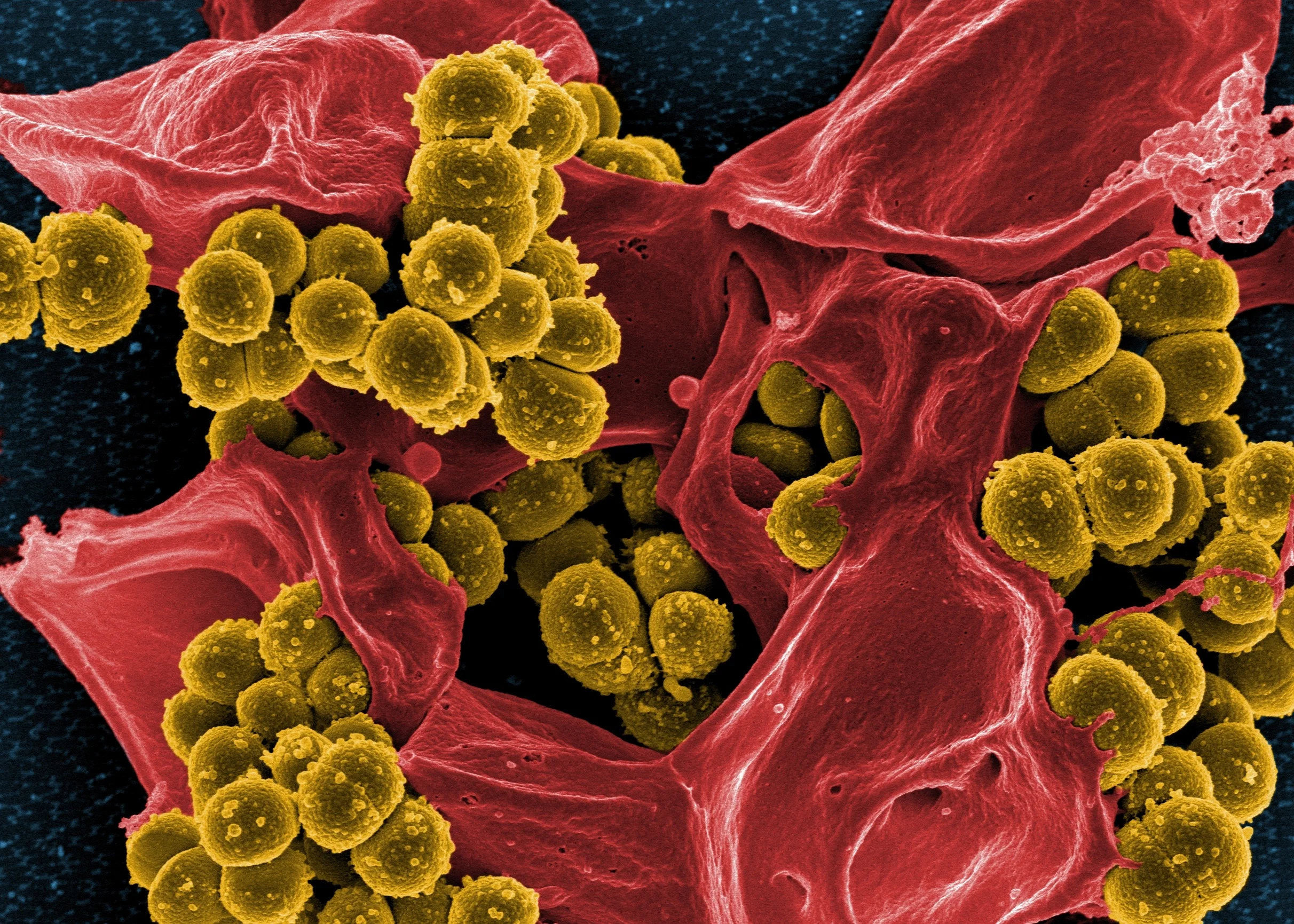

Microorganisms are always present in food production facilities. A thorough sanitation program should be in place to ensure that organisms coming into the facility are not allowed to become permanent residents.

Pathogens can be introduced into the environment via ingredients, equipment and people. The processing environment is dynamic and these daily changes require ongoing sanitation and ongoing monitoring.

Development of an Environmental Program

What and where to test

The 4-zone approach has become the standard in the food industry and relates the risk to the proximity of food production.

- Zone 1: food contact surfaces

- e.g. tables, conveyor belts, utensils, tubing, etc.

- Zone 2: non-food contact surfaces adjacent to Zone 1

- drip shields, equipment framework, control panels, etc.

- Zone 3: borders Zone 2 and is further from direct product contact but could still present risk.

- floors, walls, drains, doorways, trash cans, pallets, etc.

- Zone 4: areas away from production but still include traffic of employees and equipment that could cause cross contamination

- break rooms, restrooms, receiving docks, storage, cooler floor, etc.

It is critical to test for pathogens as well as the overall effectiveness of the facility’s standard sanitation operating procedures (SSOPs). These should both be covered in a thorough, ongoing environmental testing program to ensure that you are protecting your environment, and as a result, your consumers and your brand.

Drains are notorious for harboring Listeria – this should always be considered a key area to test.

When to test

Frequency of testing should be related to the risk potential – give precedence to areas where activity/traffic is higher and areas that are often wet and have open drains. Consider that the food processing area is always changing and that infrequent testing does not present an adequate picture of the changes that occur over time.

How to test

There are multiple types of tools available to obtain an environmental sample such as:

- Swabs (of various types)

- Sponges

- Sponge-on-a-stick

Please Contact MarketFresh so we can work together to determine the best tools to use for your needs and how to use them.